If you’ve ever looked at a flawless 3D print and wondered, “Why don’t mine turn out like that?”, you’re not alone. The magic of great 3D printing doesn’t just come from the machine. A huge part of the final result comes from how you choose, handle, and tune your filament. Today, we’ll break down three practical tips that instantly level up your print quality, durability, and overall success rate. This isn’t about complicated engineering formulas or endless slicer experiments. It’s about mastering the basics that most beginners overlook but pros refuse to ignore.

Choose the Right Filament for Your Project

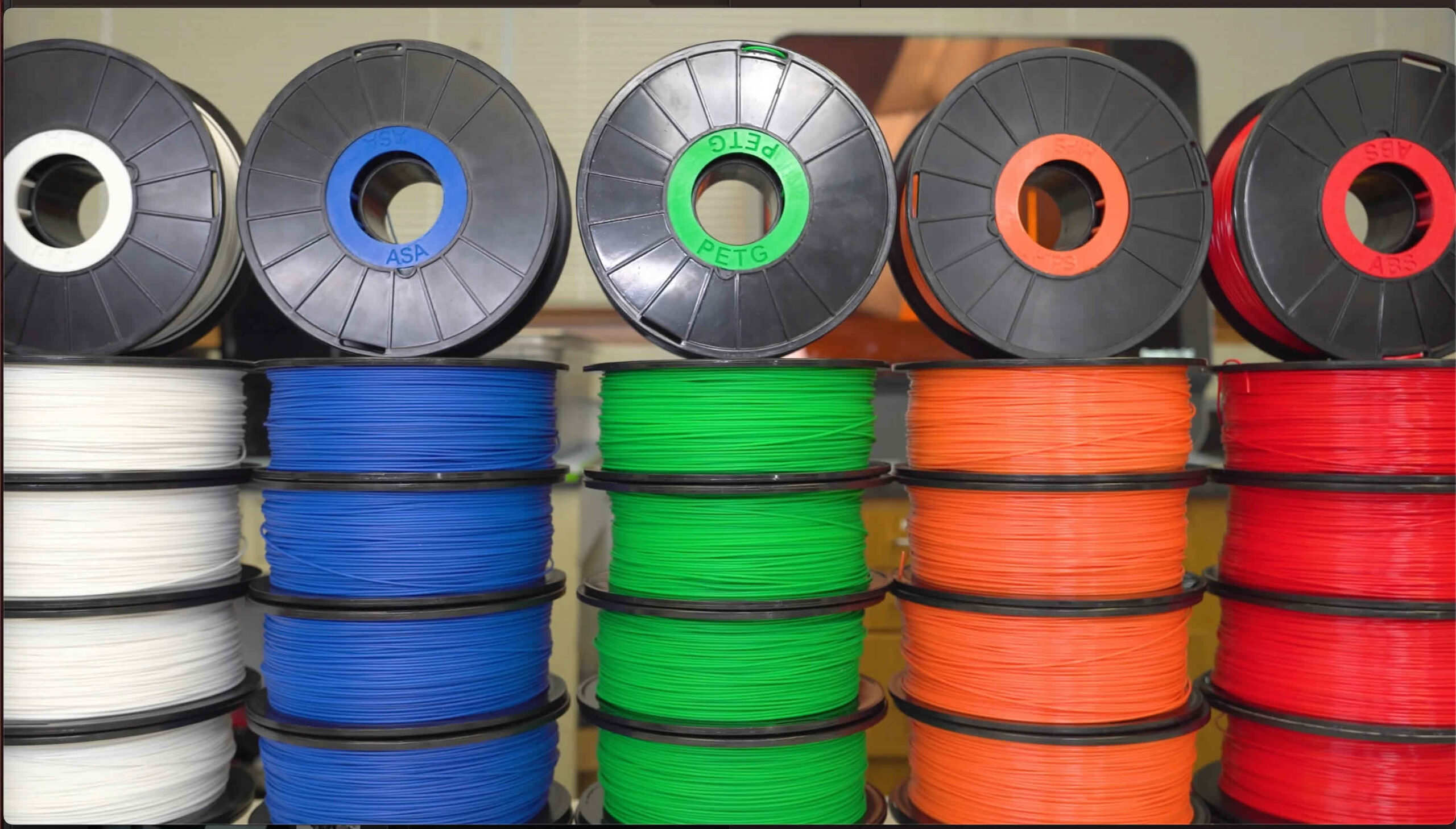

Every great print starts with the right material. Think of filaments like wood types for furniture making: pine and oak aren’t swapped just because they’re “both wood.” Same story here.

Understanding core materials

Different filaments shine in different situations:

- PLA: Easiest to print, great for prototypes, decor, and educational projects

- PETG: Stronger and more heat-resistant, ideal for functional parts

- ABS: Sturdy and temperature-resistant, better for enclosures and automotive uses

- TPU: Flexible and impact-resistant for phone cases, knobs, and gaskets

When in doubt, think about your model’s lifestyle.

- Will it sit on a desk? PLA wins.

- Will it hold weight or live outdoors? PETG steps in.

- Does it need to bend? TPU is your friend.

And if you want consistent, clean filament that behaves like you expect every time, the best 3D printer filament from FilaLab collection offers high-purity, stable materials trusted by designers and engineers.

Store & Prepare Filaments Properly

No one talks about this enough: moisture is the silent killer of print quality. Even if your filament looks fine, a humid room can load it with moisture, leading to stringing, rough surfaces, bubbling, and weak layers.

Easy storage habits

- Keep spools in airtight boxes or zipper bags

- Add silica gel packs to absorb moisture

- Consider a filament dry box if you print often

Pre-print ritual

Before printing:

- Run filament through a microfiber cloth to remove dust

- If you hear popping or see stringing, dry the roll (45–55°C depending on material)

These tiny steps make a huge difference in layer strength and finish.

Dial in the Perfect Print Settings

Even premium filament needs the right settings to shine.

Temperature tuning

Different filaments behave differently even if they’re from the same brand. Start with manufacturer recommendations, then adjust:

- Too low temp = weak layers and dull surfaces

- Too high temp = stringing and blobs

Cooling & retraction

Cooling helps sharp corners and smooth surfaces, but not all filaments want blast-fan mode. PLA loves airflow. PETG and ABS? Not so much.

Retraction settings stop stringing. Test a retraction tower once and reuse that setup forever.

Bed adhesion matters

A well-leveled bed and clean surface beat expensive add-ons.

Try:

- Glue stick

- PEI sheet

- Brim for warp-prone filaments